From Alpaca to Spinning Wheel

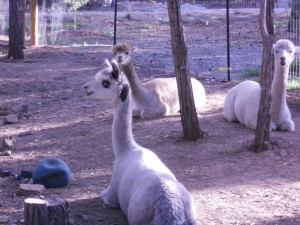

Yesterday we talked with a woman who wanted to know the process we use to get fiber from our alpacas to a finished product. I thought we might share it here.As you can see, our alpacas would not stay clean on their own. Although we do put a cover on them in the fall, they will get dirt, hay, pine needles and a few sticks in their fiber. The covers greatly reduce the debris that gets into their fiber.

Yesterday we talked with a woman who wanted to know the process we use to get fiber from our alpacas to a finished product. I thought we might share it here.As you can see, our alpacas would not stay clean on their own. Although we do put a cover on them in the fall, they will get dirt, hay, pine needles and a few sticks in their fiber. The covers greatly reduce the debris that gets into their fiber.

First we have to have the alpacas shorn. We do this once a year. You can see a video here of Yuri being shorn.

This project we will be using Svengali’s fiber. Sven is the fawn boy at the back of the picture.

The next steps we take in our fiber processing is to first skirt it. That means sorting out like fiber. Fiber in different areas are good for different things and you want to keep like fiber with like fiber. We also remove major debris at this time.

Following skirting is the cleaning stage. I like doing at least two soap wash and rinse cycles. Really dirty, dusty fleece may require more. It is at this stage we decide if we are going to dye the fiber or use it in its natural color.

The cleaned fiber is put on a screen table to dry. Once dry, we begin picking it out. We get all the little specks of grass, hay, pine needles, sticks out of the fiber and pick it apart to separate the fibers. This can be very time consuming as we do it by hand. We could send this to a mill, but their turn over time is very long, and if we do it ourselves, we control the outcome.

After picking out the fleece comes carding. We use a drum carder… think pin brush on a round drum with maybe thousands of pins. This will line of the fibers so they can be spun into batts. This too is another time consuming step. Batts can be used as they are, or put into rovings for spinning. We think it all is time well spent.